Advantages of Pulsed MIG Welding

- Nov 6, 2018

- 2 min read

Some of the key advantages provided include:

Improved Productivity

Pulsed MIG offers high deposition rates. In addition, since the new machines are simpler and adaptive, it is easier to weld with pulsed MIG than other transfer methods, this results in less time spent training.

Consumable Savings

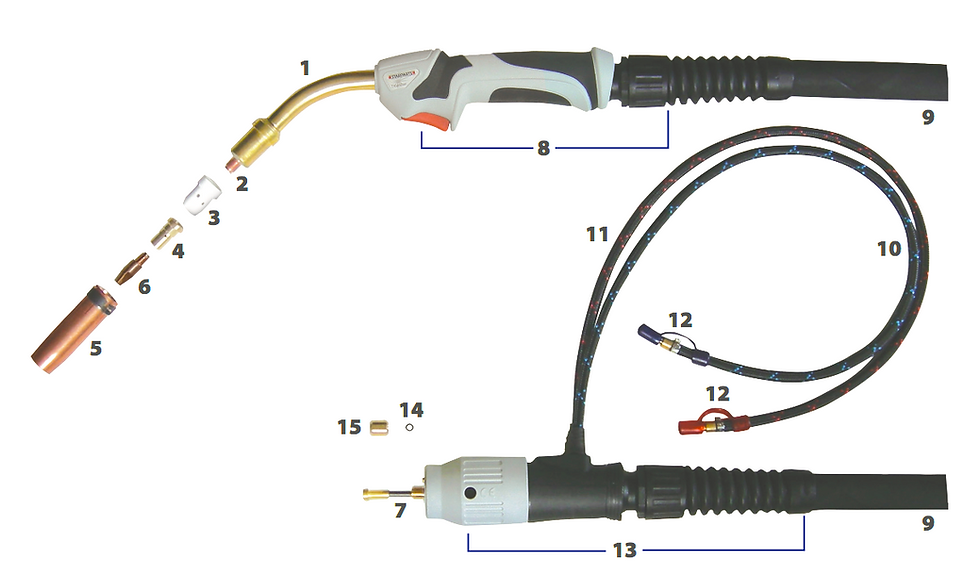

The Pulsed MIG machines due to their control offer a wider operating range as they extend the low and high range of each wire diameter. Therefore, instead of using and stocking several different wire diameters to cover different applications for example 0.8, 1.0, 1.2mm one wire size 1.2mm can be used. This in turn results in better pricing for more volume purchases of the one size wire, one size consumables (Mig torch, tips, liners, etc.) and reduced changeover labour costs as there is no need to keep changing feed rolls and other consumables.

Improved Weld Quality

All the advantages of Pulsed MIG process result in overall better quality of the finished weld. The more stable arc and spatter free welding, results in labour savings in weld finishing and additional clean up and grinding. The technology of these power sources also provide these high quality welds to be made by welders with relatively less training.

Spatter and Fume Reduction

Compared to conventional MIG/MAG, Pulsing offers reduced spatter and fume. A reduction in weld spatter results in cost savings because more of the melted electrode wire is transferred to the weld joint and not as waste surface spatter on the product and surrounding work area. A reduction in the welding fumes creates a safer and healthier environment for the work area and workshop in general.

Heat Reduction

Pulsing offers controlled heat input leading to less distortion and improved overall quality and appearance which means fewer production problems. This is especially important with stainless, nickel and other alloys that are sensitive to heat input.

Energy Saving

The new technology inverter power source is very energy efficient and many have hibernating functions which provide energy on demand and can often cost less than a 60w light bulb to run in standby mode.

Comments